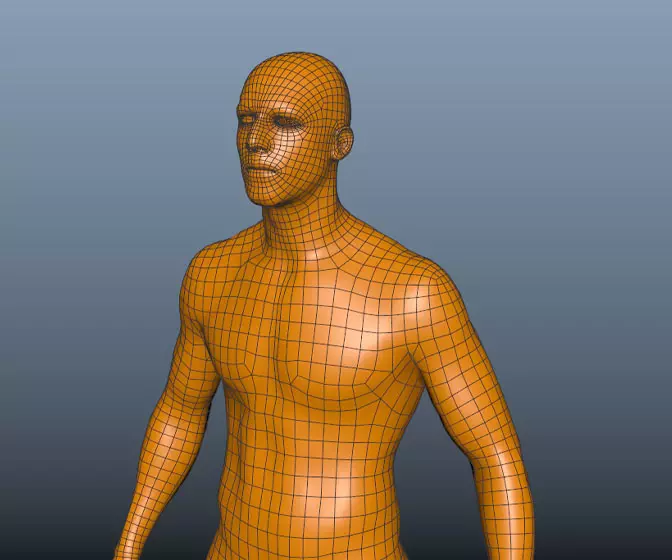

Introduction to Maya - Modeling Fundamentals Vol 2

This course will look in the fundamentals of modeling in Maya with an emphasis on creating good topology. It's aimed at people that have some modeling experience in Maya but are having trouble with

complex objects.

#

1

03-05-2003

, 11:38 AM

Using MEL to create objects

I´m making a little item to "3D scan" cars.

Uses a micro-controller chip wich I progrram myself.

I could either store coordinates locally on the EEPROM, and then read it out and put it into a file, wich then is imported into maya through a MEL script, or Icould integrate a UART interface in the microcontroller, and make it send a "live feed" to the computer COM port, and read it directly into maya using MEL.

The reason for doing this is that I want to get the car into 3D and then be able to apply and customise various styling gear and in turn export the models of the customised stylig gear to a 3D mill.

Any pointers to where I can find out more about that kind of MEL scripts? (The part that involves reading data fom my 3D scanner)

-DX-

#

2

03-05-2003

, 05:00 PM

Registered User

Join Date: Apr 2003

Join Date: Apr 2003

Location: lahore

Posts: 26

very nice work..just wanna appriciate

very first, very nice and impressive

i really wanna appriciate suce nice work

what i could say: if i will be the user never prefer for file storing and then loading data to maya for creation

there must be some middle ware thing that integrate run time to show real time creation of that data coming through port

sorry guy, i really can't help u out but

good luck and best wishes....

keep it up

haseeb

u can do it

#

3

03-05-2003

, 05:37 PM

It's farily easy to read thru a file and set keyframes etc and i'm sure that it's just as easy to set the points on a curve.

Post again with some more specfics and I'll point you in the right direction.

Alan

#

4

03-05-2003

, 05:42 PM

I´ll be watching this thread´s development closely.

adldesigner

Caracas, Venezuela

Hell .. not gone perse, but with a certainly lower post count per day.

#

5

03-05-2003

, 06:25 PM

Subscriber

Join Date: Jan 2003

Join Date: Jan 2003

Location: Denmark

Posts: 338

for my final exam project I played a bit with drivers... mostly USB... but I also looked at some other drivers... to try to learn how it worked etc...

unfortunately I don't know much about MEL scripting yet... I'm mostly educated in Java... and have played a bit with VB and C++... but I would like to help if I can...

do you e.g. have some more info about your scanner?

regards

Strarup

#

6

03-05-2003

, 08:11 PM

)

)

#

7

06-05-2003

, 05:10 PM

(Posted at Haakonsvern Naval Base)

I´ve been doing quite alot of various VB stuff, and have found some nice DLLs to use, but I think the INOUT.DLL could be called by any windows application regardless of development language.

For the 3D scanner... I´ve not actually built it yet, but I´ve been working on some ideas.

The core is an ATMEL AT8515S for those who know microcontrollers. It´s a 8 bit RISC processor, running at up to 8MHz.

The first thought was to build a rig that was driven by step-motors, scanning the entire surface of the car using a laser-beam, but I dropped the idea, cause there is a slight problem using light rays for distance measurements: For a accuracy of +/- 1meter the meaure circuit would have to run at 300MHz !!! and for 1 mm (millimeter)... You figure it out

So I kinda dropped that thought, and changed my mind. I think I´ll go for a simpler and more lightweight rig, that is manually operated. It´s a rig that can move over the car, much in the same way as the small fully automated car-washers you´ll find in almost all small gas stations in Norway, only it´s not powered by engines, and made from very lightweight components.

It has digital encoders on all axis, and a little button on a handle, and each time the button is pushed, it stores X,Y and Z coordinates, or send it straight to the computer (I haven´t desided wich metode i´ll use) With this aproach, I´ll have more control of what data I actually get. I could trace the outline of the bonnet, roof and windscreen, and use birail or birail+ to create the surfaces from the CV curves generated by the MEL-script.

It´s not as cool as the fully automated, but it´s easier to build and ALOT cheaper, alltho´I haven´t given up that idea either. There is just one problem: I´m in the army right now (all Norwegian men have to complete one year of military service. Undseth (did I spell it right?) could tell you more) and that reduces the time I get to spend on my computer and in the workshop, but I got alot more time to think about stuff , and come up with ideas.

Right now I´m drawing a fully automated system that uses one laser, wich moves across one plane of the car, and a ultra acurate detector wich locates the laser "dot" on the car surface, and from the angle of the laser and the detector, It should be possible to calculate the distance, but It´s gonna be slow, and the coding of the microchip wil be quite advanced.

A bit off-topic but If you have ideas on a different design, please post!

-DX-

#

8

06-05-2003

, 05:26 PM

Roland´s LPX-250 model is selling at about 9000$, and it´s one of the cheapest around. (non-contact model)

So I guess this could be a cheaper alternative, although time costly .. not to mention what it could do to your mental health.

adldesigner

Caracas, Venezuela

Hell .. not gone perse, but with a certainly lower post count per day.

Last edited by adldesigner; 06-05-2003 at 05:41 PM.

#

9

06-05-2003

, 05:44 PM

.. yours looks like an industrial-sized 3d scanner.

This is one of the most interesting topics ever to grace this site.

adldesigner

Caracas, Venezuela

Hell .. not gone perse, but with a certainly lower post count per day.

#

10

06-05-2003

, 06:06 PM

(Still at Haakonsvern Naval Base)

I thought I´d mentione it for some people here at the base. I know a couple of guys who knows about this stuff too, but If you could get some input, it would be really cool.

I´ll be back with more info later on.

(This project have been on my mind since I started 3D modelling. I think if I can make it work, I´ll post info about how I did it, MEL script, Processor code and other scematix related (PCB-layouts and where to get the parts cheap. By the way... Outdated Xerox machines area great source for step-motors and power-electronics.)

-DX-

#

11

06-05-2003

, 06:25 PM

Re: (Still at Haakonsvern Naval Base)

I for instance will be very gratefull.Originally posted by DukerX

I´ll post info about how I did it, MEL script, Processor code and other scematix related (PCB-layouts and where to get the parts cheap. By the way... Outdated Xerox machines area great source for step-motors and power-electronics.)

Seems a very good proyect.

adldesigner

Caracas, Venezuela

Hell .. not gone perse, but with a certainly lower post count per day.

#

12

14-05-2003

, 05:17 PM

On the PC, I´ve been using "hyper terminal" to comunicate with the chip,and been able to send and receive data from it. It was even easier than I expected!

When the button on the scanner is pressed, the chip sends the coordinates to the COM-port, one byte at the time, and the data is sent back to the chip to verify it, and if it´s okay, it proceeds to the next byte.

Since hyper terminal is not a programming interface, I had to type the data back manually, but at least, it proves that it works. The only thing I need now, is a script sample on handling terminal functionality through the COM port, and it´s working (at least the comunication between MAYA and the scanner).

The next part wil be designing the position encoders, and get that data from the position sensors into the microchip, nd alsoensure the accuracy of the entire design. At this point I´ve encountered a problem. No matter how light-weight I make it, the material would still flex and bend when I move the point-scanner over the car surface, so I´m also working on a device to make it semi-automated, much in the same fashion as the power steering on a car.

Final note...

I could post code samples and scematics much like the WIP part of this forum, but the various parts wouldn´t be much good without the entire design, and they´re also due to change whenever I make modifications and improvements, but on the other hand, the people that reads this forum might get their own ideas, and could help me with the design.

-DX-

#

13

15-05-2003

, 11:38 AM

x,y,z trans I can give you a script to load them into maya. That would avoid the need to write a plugin. Does that help at all?

Alan

#

14

17-05-2003

, 11:08 AM

What kind of object is created in maya?... Or is that customisable??

-DX-

#

15

19-05-2003

, 11:41 AM

let me think about it.

Alan

Posting Rules Forum Rules

Similar Threads

using mel to select multiple objects

by davad138 in forum Programming replies 2 on 29-01-2020

create line from objects

by ssimon12 in forum Maya Basics & Newbie Lounge replies 3 on 27-07-2011

Renaming Objects using MEL Scripts

by oneshotflinch in forum Maya Basics & Newbie Lounge replies 0 on 21-10-2005

Rename Objects using MEL Scripts

by oneshotflinch in forum Programming replies 0 on 21-10-2005

How can I list all objects in a Maya scene in a roll-down list with MEL?

by vern in forum Programming replies 5 on 01-09-2003

Topics

Free Courses

Full Courses

VFX News

How computer animation was used 30 years ago to make a Roger Rabbit short

On 2022-07-18 14:30:13

Sneak peek at Houdini 19.5

On 2022-07-18 14:17:59

VFX Breakdown The Man Who Fell To Earth

On 2022-07-15 13:14:36

Resident Evil - Teaser Trailer

On 2022-05-13 13:52:25

New cloud modeling nodes for Bifrost

On 2022-05-02 20:24:13

MPC Showreel 2022

On 2022-04-13 16:02:13